With Future of robotics at the forefront, this exploration delves into the exciting advancements and implications of robotic technology. From its historical roots to the innovative applications emerging today, we’ll uncover the potential of robots to transform various sectors, including healthcare, manufacturing, and space exploration.

The rapid evolution of robotics, driven by artificial intelligence and collaborative design principles, is reshaping our world. This journey examines the key components of robotic systems, the latest trends in robotic design, and the ethical considerations surrounding their increasing integration into society. Furthermore, the economic impact and potential challenges of this technological revolution are also considered.

Introduction to Robotics

Robotics, a rapidly evolving field, encompasses the design, construction, operation, and application of robots. Its roots trace back to ancient myths and legends, but significant advancements emerged in the 20th century, driven by technological breakthroughs and growing industrial needs. Early robots were primarily simple, programmable machines designed for repetitive tasks. Today, robots are sophisticated systems capable of complex actions, often interacting with the environment and humans in intricate ways.The field has evolved from simple automation to complex systems capable of learning, adapting, and even exhibiting some degree of intelligence.

This evolution has led to robots being deployed across a broad spectrum of industries, each leveraging the unique capabilities of robotic systems. Understanding the fundamental principles of robotics is crucial for comprehending its current applications and potential future developments.

Historical Development of Robotics

Early forms of automation date back centuries. The development of robotics, however, accelerated significantly in the 20th century. Key milestones include the creation of programmable industrial robots, the development of artificial intelligence (AI) algorithms, and advancements in sensor technology. These advancements paved the way for more sophisticated robots capable of performing increasingly complex tasks.

Types of Robots and Their Applications

Robots are categorized based on their structure, functionality, and intended use. Industrial robots, frequently employed in manufacturing settings, are characterized by their repetitive and precise movements. Examples include robotic arms for welding, painting, and assembly tasks. Service robots, designed for tasks that involve human interaction, are utilized in healthcare, hospitality, and personal assistance. Examples include surgical robots and automated vacuum cleaners.

Exploration robots, engineered for harsh or inaccessible environments, play a critical role in space exploration, underwater research, and disaster relief. Examples include rovers on Mars and underwater drones.

Key Components of a Robotic System

A robotic system is a complex interplay of interconnected components. The core elements include actuators, sensors, a control system, and a power source. Actuators provide the mechanical force for movement. Sensors gather information about the robot’s environment. The control system processes sensor data and coordinates actuator actions.

The power source fuels the robot’s operations. The sophistication of these components directly impacts the robot’s capabilities and performance.

Comparison of Robotic Types

| Robot Type | Strengths | Weaknesses |

|---|---|---|

| Industrial Robots | High precision, repeatability, and speed in performing repetitive tasks; Cost-effective for large-scale production; Reduced human error potential | Limited adaptability; Often require specific programming for each task; Can be expensive to install and maintain |

| Service Robots | Can assist humans in various tasks, improving efficiency and safety; Can operate in dynamic environments; Able to interact with humans in a more natural way | Often have limited dexterity and strength compared to industrial robots; Cost can be high; Can be prone to malfunction or require extensive maintenance |

| Exploration Robots | Can operate in harsh or inaccessible environments; Can collect data and images in remote locations; Can perform dangerous tasks | Often require specialized design for the specific environment; Limited mobility and dexterity in some cases; Can be expensive to develop and operate |

Emerging Trends in Robotics

Robotics is rapidly evolving, driven by advancements in artificial intelligence, materials science, and computing power. This evolution is leading to more sophisticated and versatile robots capable of performing tasks previously considered impossible. These developments are transforming industries from healthcare to agriculture and promise to reshape our world in profound ways.

AI Integration in Robotics

AI is fundamentally changing robotic capabilities. Sophisticated algorithms allow robots to learn from experience, adapt to new environments, and make decisions autonomously. Machine learning enables robots to recognize objects, navigate complex spaces, and perform tasks with a level of precision previously unattainable. Deep learning models, in particular, are driving significant improvements in robotic perception and decision-making. For example, self-driving cars rely heavily on AI algorithms for object recognition and path planning.

Similarly, robots in manufacturing settings are utilizing AI for quality control and process optimization.

The future of robotics is looking pretty promising, with advancements in AI and materials science driving incredible innovation. Think about how these advancements might impact the design of jewelry, like a pear-shaped diamond, pear shaped diamond for example. Ultimately, these advancements in both areas are poised to shape the way we interact with technology and the world around us.

Collaborative Robots (Cobots)

Cobots are designed for safe and effective collaboration with humans in shared workspaces. Their key characteristic is their ability to operate alongside humans without the need for extensive safety precautions. This collaborative approach increases productivity and flexibility in manufacturing, assembly, and other industries. Features like force sensing and advanced safety protocols are crucial to this collaboration. For instance, cobots are increasingly used in packaging and assembly lines, allowing for more dynamic and flexible production processes.

Nanorobotics

Nanorobotics, while still in the early stages of development, holds enormous potential for various applications. These microscopic robots, capable of operating at the cellular level, could revolutionize medicine, enabling targeted drug delivery, precise surgical interventions, and the diagnosis of diseases at their earliest stages. Challenges remain in developing robust and controllable nanorobotic systems. Potential applications include personalized medicine and addressing complex diseases like cancer.

Robotics in Healthcare

Robotic surgery systems are already revolutionizing surgical procedures, offering enhanced precision, dexterity, and reduced invasiveness. Surgical robots are capable of performing minimally invasive operations with remarkable accuracy. For example, the da Vinci surgical system is widely used for various surgical procedures. Further advancements could lead to more complex procedures, including the repair of damaged organs. In addition to surgery, robots are also being employed for physical therapy, rehabilitation, and patient care.

Robotics in Agriculture

Agricultural robots are being deployed to automate tasks like planting, harvesting, and crop monitoring. These robots can increase efficiency and reduce labor costs in farming. Precision agriculture techniques utilize robots for targeted application of fertilizers and pesticides, maximizing crop yields while minimizing environmental impact. Furthermore, drones are increasingly used for aerial surveillance and crop monitoring, enabling farmers to make data-driven decisions about their fields.

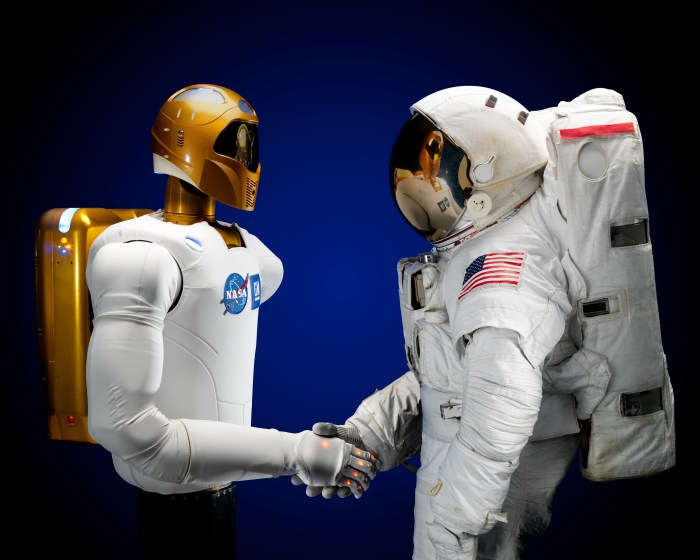

Robotics in Space Exploration

Robots play a vital role in space exploration, enabling humans to explore environments too dangerous or remote for direct human presence. Space robots are capable of performing complex tasks, including sample collection, data analysis, and scientific experiments. For example, rovers on Mars are collecting invaluable data about the planet’s geology and potential for past or present life. Further advancements could involve deploying robots for the construction of space habitats or mining of resources in space.

Optimizing for Efficiency and Safety

The efficiency of robotic systems can be improved by optimizing their algorithms, control systems, and physical designs. This includes reducing energy consumption, improving speed and precision, and enhancing their adaptability to changing environments. Robotic safety is paramount. Integrating safety features, such as sensors, emergency stops, and fail-safe mechanisms, is crucial to minimize risks and ensure the safety of human operators and the environment.

This approach minimizes potential hazards.

The Future of Robotic Design

The future of robotics hinges on innovative design considerations. These considerations will dictate the capabilities and limitations of robots in diverse applications. From materials science to energy efficiency, the next generation of robots will require a holistic approach to problem-solving. The adaptability of these machines to dynamic environments will be crucial for their widespread adoption.Future robotic design will prioritize adaptability and efficiency, aiming for a seamless integration with human environments.

Key factors in this evolution include the selection of appropriate materials, reliable energy sources, and advanced control systems. The quest for sustainable development will also shape the future trajectory of robotic design, demanding environmentally friendly solutions.

Materials for Future Robots

Material selection will significantly impact a robot’s performance. Lightweight, high-strength materials will be essential for improving mobility and reducing energy consumption. Composite materials, incorporating advanced polymers and carbon fiber, offer promising solutions. Additionally, self-healing materials could enhance durability and reduce maintenance needs. The use of 3D printing will enable complex geometries and customized designs, further optimizing robotic performance.

Energy Sources for Future Robots

The development of efficient and sustainable energy sources is paramount. Robots will increasingly rely on renewable energy sources like solar power and wind energy. Furthermore, advancements in battery technology, including solid-state batteries and high-energy density cells, will significantly extend operational time. Hybrid systems combining multiple energy sources will provide flexibility and resilience in dynamic environments. Research into energy harvesting from ambient sources like vibrations and heat is also promising.

Control Systems for Future Robots

Advanced control systems will be critical for enabling robots to operate autonomously and adapt to unpredictable situations. Artificial intelligence (AI) and machine learning (ML) will play a central role in enabling robots to learn from experience and improve their performance over time. Real-time data processing and sophisticated algorithms will enhance decision-making capabilities in complex environments. Furthermore, the integration of human-robot interaction (HRI) will allow for seamless collaboration.

Adaptability to Dynamic Environments

Robots must be able to adapt to changing conditions. This includes adapting to varying terrains, unpredictable movements of objects, and unforeseen obstacles. Sophisticated sensors, including advanced cameras, lidar, and radar, will provide robots with a comprehensive understanding of their surroundings. Furthermore, the ability to quickly adjust movements and strategies based on real-time data will be vital. These adaptable features are critical for success in applications such as disaster response and exploration.

Potential Robotic Designs for Various Tasks

| Task | Potential Design | Description |

|---|---|---|

| Search and Rescue | Quadruped robot with thermal imaging | Agile movement on uneven terrain, enhanced vision for identifying survivors. |

| Construction | Modular robot with interchangeable arms and tools | Adaptable to various construction tasks, optimized for specific needs. |

| Agriculture | Autonomous tractor with sensor-guided harvesting | Precise crop monitoring and harvesting, reduced human intervention. |

| Manufacturing | Collaborative robot arm with AI-driven control | High precision and speed, adaptable to different manufacturing processes. |

Sustainability in Robotic Development

Sustainability is an integral part of robotic design. The lifespan of robots should be extended, and their manufacturing processes must be environmentally responsible. The use of recycled materials in construction will be crucial, and minimizing energy consumption during operation is vital. The long-term environmental impact of robots needs to be carefully considered. The design, manufacturing, and operational phases must be examined from a sustainability perspective.

Ethical Implications of Robotics

The rapid advancement of robotics presents a compelling array of possibilities, yet also raises critical ethical considerations. As robots become more sophisticated and integrated into daily life, we must carefully examine the potential societal impacts, particularly concerning job displacement and human-robot interaction. Addressing potential biases within these systems is paramount to ensure equitable access and outcomes for all.

Robust regulations and ethical guidelines are crucial for responsible development and deployment.

Job Displacement and Economic Impacts

The automation potential of robots necessitates careful consideration of its impact on the workforce. While robots can enhance productivity and efficiency in various sectors, concerns about job displacement are valid. Analysis of past technological advancements reveals similar patterns of transition and adaptation, necessitating proactive strategies for retraining and reskilling programs. Government policies and private sector initiatives should collaborate to mitigate potential economic disruptions and ensure a smooth transition.

For example, the rise of automated manufacturing processes in the automotive industry has prompted workforce retraining initiatives, focusing on skills that complement automation rather than replace them.

Bias in Robotic Systems

Robotic systems are trained on vast datasets, and if these datasets reflect existing societal biases, the robots will perpetuate and potentially amplify those biases. This can lead to discriminatory outcomes in areas such as loan applications, hiring processes, or even criminal justice. For example, facial recognition systems trained on predominantly white datasets may perform less accurately on individuals from other racial groups, leading to misidentification and unfair treatment.

Addressing bias in robotic systems requires careful attention to data selection, algorithm design, and ongoing evaluation to ensure fairness and equity.

Safeguards and Regulations for Responsible Development

Establishing clear ethical guidelines and regulations is essential to govern the development and deployment of robots. These guidelines should address issues such as data privacy, transparency in algorithms, accountability for robotic actions, and potential harm caused by malfunctions. International collaborations and standardization of ethical principles are vital to ensure consistency and prevent a fragmented approach to regulating this rapidly evolving technology.

International cooperation and agreements on standards for ethical development will be essential as robotics systems transcend national borders.

Scenarios of Advanced Robotics and their Ethical Implications

The future holds the potential for advanced robotics to impact diverse aspects of human life, from healthcare and education to law enforcement and military applications. The deployment of robots in autonomous vehicles raises questions about liability in case of accidents. Autonomous weapons systems introduce complex considerations regarding accountability and the potential for unintended consequences. Furthermore, the use of robots in healthcare settings requires careful consideration of patient autonomy and the role of human medical professionals.

Ethical guidelines should be developed for these applications to ensure their use aligns with human values and safety.

Human-Robot Interaction

As robots become more integrated into human society, the quality of human-robot interaction becomes a significant concern. Developing robots with intuitive and empathetic interfaces is crucial to fostering trust and collaboration. Ensuring robots do not perpetuate stereotypes or create dependency is essential. Understanding how humans interact with robots is crucial for the successful development and deployment of these systems.

Designing robots that understand and respond to human emotions and needs in a beneficial way will be critical for fostering successful human-robot partnerships.

Robotic Collaboration and Human-Robot Interaction

Robotic collaboration is rapidly evolving, moving beyond simple automation to encompass sophisticated human-robot interaction. This shift necessitates careful consideration of the benefits, challenges, and ethical implications of these partnerships in various work environments. The future of work will increasingly involve robots as partners, collaborators, and even companions. Understanding the dynamics of human-robot interaction is critical for maximizing the potential of this new paradigm.Effective human-robot interaction hinges on a robust understanding of how humans and robots can work together efficiently and safely.

This includes developing training programs, designing intuitive interfaces, and addressing the potential social impact of these partnerships. The seamless integration of robots into our daily lives requires a holistic approach that considers the psychological, social, and practical aspects of human-robot interaction.

Benefits and Challenges of Human-Robot Collaboration

Human-robot collaboration offers numerous advantages in diverse work settings. Increased productivity and efficiency are often observed due to robots’ ability to handle repetitive tasks or operate in hazardous environments. For instance, in manufacturing, robots can perform intricate assembly tasks with precision, freeing human workers for more complex and creative roles. However, challenges also arise. Ensuring safety and minimizing the risk of human error or robot malfunction are paramount.

Maintaining clear lines of communication and responsibility in collaborative tasks is crucial to avoid misunderstandings and ensure accountability.

Methods for Training Human-Robot Interaction

Training programs must equip human workers with the skills necessary to interact safely and effectively with robots. This includes practical training on robot operation protocols, safety procedures, and maintenance. Simulation environments, where humans can practice interacting with robots in controlled settings, are vital for developing confidence and familiarity. Training should also focus on communication techniques to improve clarity and efficiency in human-robot interactions.

Understanding the capabilities and limitations of the robots will be critical for effective training. Furthermore, a multi-faceted approach, combining theoretical knowledge with practical experience, is essential.

Impact of Human-Robot Interaction on Social Dynamics

The integration of robots into workplaces and daily life can significantly impact social dynamics. Increased automation may lead to concerns about job displacement and require adjustments in social structures. Collaborative robots can create new job roles and require re-skilling of the existing workforce. Careful consideration of the potential social consequences of human-robot interaction is necessary. The integration of robots can foster a sense of partnership and shared responsibility in various settings, leading to more efficient and productive work environments.

Furthermore, robots may impact interpersonal relationships between colleagues and supervisors, which warrants consideration.

Potential Interfaces for Human-Robot Communication

Effective communication between humans and robots is critical for successful collaboration. Various interfaces can facilitate this interaction, including voice commands, gesture recognition, and tactile interfaces. Haptic feedback systems can provide intuitive feedback to the human operator, allowing for a more natural and intuitive interaction. Natural language processing (NLP) allows for human-robot interaction through spoken language, potentially eliminating the need for complex programming.

The design of these interfaces should prioritize ease of use, safety, and efficiency to enhance the human-robot partnership. The development of more sophisticated and intuitive interfaces will be crucial for widespread adoption of human-robot collaboration.

Robotics and Automation in Manufacturing: Future Of Robotics

The manufacturing sector is undergoing a significant transformation driven by the increasing adoption of robotics and automation. This shift is impacting everything from production lines to supply chains, promising increased efficiency, reduced costs, and enhanced product quality. This evolution necessitates a nuanced understanding of both the current state of automation and its future potential.

Current State of Automation in Manufacturing

The current landscape of manufacturing automation features a diverse range of robots and automated systems. Collaborative robots (cobots), designed for safe interaction with human workers, are gaining prominence in tasks requiring dexterity and flexibility. Industrial robots, often employed in repetitive tasks like welding, painting, and material handling, are highly prevalent in many factories. Automated guided vehicles (AGVs) are widely used for transporting materials and components throughout the facility.

Advanced technologies like machine vision and AI are increasingly incorporated into automated systems to enhance their capabilities and decision-making processes. The integration of these systems varies widely across industries, from automotive to electronics manufacturing.

Future Potential of Robotic Automation in Manufacturing

The future of robotic automation in manufacturing is promising, driven by continuous advancements in robotics, AI, and machine learning. Predictive maintenance, powered by AI algorithms analyzing sensor data, can anticipate equipment failures, minimizing downtime and improving overall operational efficiency. Personalized manufacturing, enabled by adaptive robots and AI-driven systems, allows for customized products and flexible production runs. This adaptability and personalization is becoming increasingly important in meeting the evolving demands of customers.

Enhanced safety features in cobots are reducing the need for specialized safety enclosures, making automation more accessible and safer for human workers.

Benefits of Robotic Automation in Improving Production Efficiency and Quality

Robotic automation offers substantial benefits in improving production efficiency and quality. Increased speed and precision in performing tasks translate directly to higher output volumes. Robots can operate continuously without breaks, leading to round-the-clock production and reduced labor costs. Standardization of processes ensures higher quality control, reducing defects and rework. The consistent execution of tasks by robots minimizes human error, leading to greater accuracy and precision in manufacturing processes.

Strategies for Integrating Robots into Existing Manufacturing Workflows

Integrating robots into existing workflows requires a strategic approach. Careful assessment of existing processes and identification of suitable automation opportunities is crucial. Gradual implementation, starting with pilot projects, allows for testing and refinement before large-scale deployment. Training employees on the new systems and establishing clear communication protocols are essential for successful integration. A phased approach, enabling seamless integration with existing infrastructure, is also vital.

Challenges and Solutions Related to Implementing Robotic Automation

Implementing robotic automation presents certain challenges. High initial investment costs and the need for specialized expertise in programming and maintenance can be hurdles. Ensuring compatibility with existing infrastructure and addressing potential disruptions to the workforce are also important considerations. Solutions include exploring financing options for robotic equipment, developing comprehensive training programs for personnel, and implementing strategies for workforce transition and reskilling.

Careful planning and proactive communication can mitigate these challenges and pave the way for successful implementation.

Example of Successful Robotic Automation Implementation, Future of robotics

One example of successful robotic automation implementation is the automotive industry. Automakers have extensively adopted robots for tasks like welding, painting, and assembly, resulting in increased productivity and reduced manufacturing costs. The integration of advanced sensors and machine learning algorithms further enhances the precision and efficiency of these automated systems.

Robotics in Healthcare and Medicine

Robots are increasingly integrated into healthcare, offering a diverse range of applications from minimally invasive surgeries to rehabilitation assistance. Their precision, dexterity, and ability to perform repetitive tasks efficiently contribute to improved patient care and enhanced accessibility to medical procedures. This evolution promises to revolutionize various facets of healthcare, from surgical techniques to diagnostic capabilities.

Overview of Robotic Applications in Healthcare

Robotic systems are now commonplace in several medical specialties, providing a more precise and controlled environment for surgical procedures. They offer enhanced visualization, allowing surgeons to operate with greater precision and reduced invasiveness. Furthermore, robots can assist in rehabilitation, enabling tailored exercises and therapy for patients with physical limitations. Diagnostic applications are also expanding, with robots capable of performing tasks like endoscopy with increased accuracy and efficiency.

Robotic Surgery

Robotic surgery systems, such as the da Vinci Surgical System, provide surgeons with magnified, three-dimensional views of the surgical site. This enhanced visualization allows for greater precision and dexterity, enabling minimally invasive procedures with smaller incisions, reduced blood loss, and faster recovery times. These systems are increasingly used for various surgical procedures, including urological, gynecological, and general surgical operations.

The improved visualization and dexterity facilitated by robotic systems are key factors in reducing the invasiveness of surgery and optimizing surgical outcomes.

Robotic Rehabilitation

Robotic rehabilitation devices are designed to assist patients with physical therapy, particularly those recovering from strokes, injuries, or surgeries. These devices provide tailored exercises, controlled movements, and feedback, aiding in the restoration of lost motor skills. The robots adapt to the patient’s specific needs, offering a personalized approach to rehabilitation. Furthermore, the repetitive nature of many exercises can be performed with robotic assistance, promoting patient engagement and faster recovery.

For example, robotic arm exercises can help stroke victims regain movement and coordination.

Robotic Diagnostics

Robots are now being used to enhance diagnostic capabilities in various medical fields. Endoscopes equipped with robotic systems offer a less invasive and more accurate way to examine internal organs. The precision of robotic endoscopes allows for early detection of abnormalities, enabling prompt treatment and improved patient outcomes. Moreover, robotic systems can analyze medical images, assisting radiologists in identifying potential issues, improving efficiency, and potentially reducing human error.

This enhanced diagnostic capability can lead to earlier and more effective interventions.

Future of Robotic-Assisted Surgery

The future of robotic-assisted surgery is characterized by increasing sophistication and integration into various surgical specialties. The development of more advanced robotic systems with enhanced dexterity and precision will further reduce invasiveness, shorten recovery times, and improve patient outcomes. Furthermore, the integration of artificial intelligence (AI) into robotic systems is expected to enhance decision-making and improve surgical precision.

For instance, AI algorithms can analyze images and identify subtle abnormalities that might be missed by the human eye, leading to more accurate diagnoses and improved patient care. The incorporation of AI and machine learning promises to make robotic surgery even more effective and adaptable to diverse patient needs.

Robotics and the Environment

Robotics is increasingly recognized as a powerful tool for mitigating environmental challenges. From pollution control to resource management, robots are demonstrating their potential to enhance sustainability across various sectors. This section explores the significant role robots play in addressing environmental concerns and improving ecological balance.

Environmental Monitoring and Data Collection

Robots excel at performing repetitive and hazardous tasks in environmental monitoring. Their ability to gather data in remote or dangerous locations is crucial for understanding environmental conditions and trends. Automated systems equipped with sensors can continuously monitor air and water quality, soil composition, and other critical environmental parameters. This real-time data allows for early detection of pollution outbreaks and facilitates informed decision-making for environmental protection.

Pollution Control and Remediation

Robots are capable of participating in pollution control and remediation efforts. Autonomous underwater vehicles (AUVs) are employed to map and clean up ocean debris, while specialized robots are used to remove pollutants from soil and water. Their precision and efficiency in targeted interventions contribute to reducing the environmental impact of industrial processes and natural disasters. For example, robots can be deployed to contain oil spills or clean up hazardous waste, minimizing the long-term damage to ecosystems.

Resource Management and Conservation

Optimizing resource management is crucial for environmental sustainability. Robots can play a significant role in this area by automating tasks related to resource extraction and utilization. Automated systems can be employed in forestry, agriculture, and mining to ensure efficient use of resources and minimize environmental disruption. This includes precision agriculture, where robots can monitor crop health and apply fertilizers and pesticides only where needed, thus reducing chemical runoff and water pollution.

Sustainability in Industries

Robots are driving sustainability in various industries by automating processes and reducing waste. In manufacturing, robotic systems can optimize energy consumption and minimize material waste, leading to significant environmental improvements. By automating tasks that contribute to environmental problems, robotics provides a path to cleaner and more sustainable industrial practices.

Examples of Environmental Robots

- Autonomous Underwater Vehicles (AUVs): These robots are crucial for underwater exploration, mapping, and cleanup tasks. They can be equipped with sensors to monitor water quality and identify pollution sources. For instance, AUVs can collect data about ocean currents and marine life, which can then be used to develop effective conservation strategies. They are often deployed in coastal areas and open waters to map and assess environmental conditions.

- Drone-based Monitoring Systems: Drones equipped with high-resolution cameras and sensors provide valuable data on deforestation, pollution levels, and wildlife populations. This remote sensing technology is used for large-scale environmental assessments, enabling quicker responses to environmental issues and facilitating conservation efforts.

- Waste Management Robots: Specialized robots are being developed for waste sorting and recycling. These robots can automate the process of separating different types of waste, increasing recycling rates and reducing landfill burden. This helps in reducing waste disposal costs and environmental impact, as well as saving resources.

Developing Mitigating Robotic Technologies

The development of new robotic technologies is crucial for mitigating environmental impacts. This includes developing robots that are more energy-efficient, can operate with renewable energy sources, and can be designed to be easily recycled or repurposed at the end of their operational life. The design of robots with minimal environmental impact is paramount in their long-term sustainability.

Robotics in Space Exploration

Robotic spacecraft are playing an increasingly crucial role in our exploration of the cosmos. Their ability to withstand the harsh conditions of space and perform complex tasks autonomously makes them invaluable tools for understanding planetary systems and expanding our knowledge of the universe. These robotic explorers are paving the way for future human missions and offering unique perspectives on distant worlds.Robotic probes and landers, equipped with sophisticated instruments, are collecting invaluable data about the composition, geology, and potential habitability of planets and moons.

This data is then analyzed by scientists to unravel the mysteries of the solar system and beyond. Furthermore, the information gathered through these robotic missions allows for the development of more efficient and targeted future missions, optimizing resource allocation and increasing the overall success rate of space exploration endeavors.

Planetary Missions and Lunar Exploration

Robotic spacecraft are crucial for detailed planetary exploration, conducting reconnaissance and gathering scientific data that is difficult or impossible for humans to obtain directly. These missions encompass a wide range of tasks, including orbital surveys, surface landings, and sample return. Their ability to operate autonomously in extreme environments expands the scope of scientific inquiry, allowing us to examine areas inaccessible to human explorers.

The future of robotics is looking pretty promising, with advancements in AI and automation likely to reshape various industries. Think about how these advancements might impact skincare routines; perhaps future robots will be equipped to precisely apply products like estee lauder eye cream with customized precision, leading to even more effective and tailored treatments. This innovative potential holds exciting possibilities for the future of robotics in beauty and beyond.

Challenges and Opportunities in Extraterrestrial Environments

Developing robots for extraterrestrial environments presents significant challenges. These include extreme temperatures, radiation exposure, and the unique challenges of operating in a vacuum. However, these challenges also present unique opportunities. Innovations in materials science, energy storage, and communication technologies are driving advancements in robotic design. The development of resilient robots capable of functioning in these demanding environments pushes the boundaries of engineering and opens up possibilities for unprecedented scientific discovery.

The opportunity to study these harsh environments may also provide valuable insights for future human settlements.

Advancing Our Understanding of the Universe

Robotic exploration plays a vital role in advancing our understanding of the universe. By studying the composition and geological history of other planets and moons, scientists can gain insights into the formation and evolution of planetary systems. These discoveries have the potential to rewrite our understanding of celestial bodies and the potential for life beyond Earth. The data collected by robotic missions helps us to formulate hypotheses, test theories, and refine our understanding of the cosmos.

Examples of Robotic Spacecraft and Their Missions

- Curiosity Rover (Mars): This rover has extensively explored the Gale Crater on Mars, collecting data on the planet’s geology and searching for evidence of past habitability. Its findings have significantly advanced our understanding of Mars’s history and potential for supporting life.

- Cassini-Huygens Mission (Saturn): This mission, which involved both an orbiter and a lander, provided comprehensive data about Saturn’s rings, moons, and atmosphere. The findings offered insights into the formation and evolution of the Saturnian system.

- Voyager Probes (Interstellar Space): These probes have ventured beyond our solar system, providing valuable data on the conditions and composition of interstellar space. Their ongoing journey continues to broaden our knowledge of the universe beyond our solar system.

The Economic Impact of Robotics

Robotics is rapidly transforming industries, promising significant economic benefits while also presenting challenges. The potential for increased productivity, enhanced efficiency, and new market opportunities is substantial, but the transition will require careful consideration of workforce adaptation and ethical implications. The impact on employment, economic growth, and the future of work will be substantial.The economic impact of robotics extends beyond simple cost savings, encompassing the creation of entirely new industries and the reshaping of existing ones.

Automation driven by robotics can dramatically boost productivity, potentially leading to increased economic output and potentially higher standards of living. However, the shift towards automation also raises concerns about job displacement and the need for workforce retraining.

Projected Economic Impact

The future economic impact of robotics will depend on factors like technological advancements, regulatory frameworks, and societal responses. While precise projections are challenging, numerous studies and reports offer insights into potential outcomes. Some models suggest substantial economic growth driven by increased efficiency and output in various sectors, such as manufacturing, logistics, and healthcare.

Job Creation and Displacement

The introduction of robotics often leads to both job displacement and the creation of new roles. Traditional manufacturing jobs may be automated, but new roles will emerge in robotics engineering, maintenance, programming, and the development of new applications. The key to a successful transition lies in proactive workforce retraining and education initiatives that equip workers with the skills needed for the evolving job market.

Boosting Economic Growth and Productivity

Robotics can significantly boost economic growth by increasing productivity and efficiency. Automated processes can handle repetitive tasks, freeing up human workers for more complex and creative endeavors. Examples include automated assembly lines in manufacturing, robotic surgery in healthcare, and autonomous vehicles in transportation. These advancements can potentially lead to lower production costs, faster turnaround times, and increased output.

Workforce Retraining and Upskilling

The transition to a robot-driven economy necessitates significant workforce retraining and upskilling initiatives. Education programs focused on robotics, automation, data analysis, and artificial intelligence are crucial. Existing workers need opportunities to adapt their skills to new technologies, potentially through reskilling programs and apprenticeships. Government policies and industry partnerships can play a vital role in facilitating these transitions.

Robotics and the Future of Work

Robotics is fundamentally reshaping the future of work, creating new roles and responsibilities. Workers will need to adapt to collaborate with robots, learning new skills and embracing a more integrated approach to work. The focus will shift from repetitive manual labor to higher-level tasks that require critical thinking, problem-solving, and creativity. The future of work will likely involve a dynamic mix of human and robotic capabilities, each contributing unique strengths to the economic landscape.

Final Thoughts

In conclusion, the future of robotics promises a world where intelligent machines collaborate with humans in diverse fields. While opportunities abound, ethical considerations and workforce adaptation are crucial for a successful and equitable transition. The potential for innovation is vast, promising breakthroughs in areas like healthcare, environmental sustainability, and space exploration. The discussion highlights the multifaceted impact of robotics and the importance of responsible development to harness its transformative power.

Helpful Answers

What are the biggest ethical concerns surrounding the development of advanced robotics?

Potential job displacement, bias in algorithms, and the need for responsible development and deployment are key ethical concerns. These require careful consideration to ensure fairness and prevent unintended consequences.

How can we ensure that robots are used to benefit society in a sustainable way?

Sustainable practices in robotic design, including material choices and energy sources, are critical. Furthermore, the focus should be on applications that improve environmental conditions and resource management.

What are some examples of robots used in healthcare today?

Robots are used in surgery, rehabilitation, and diagnostics, improving patient care and accessibility. Robotic-assisted surgery is advancing, offering enhanced precision and minimally invasive procedures.

How will the increasing use of robots affect the workforce?

While robotics may displace some jobs, it also creates new opportunities in fields like robotic maintenance, programming, and design. Workforce retraining and upskilling programs are essential to adapt to this evolving job market.