Transistor specs delve into the intricate world of semiconductor components. Understanding these specifications is crucial for selecting the right transistor for any given electronic circuit. This guide covers everything from different transistor types and their electrical characteristics to packaging, frequency response, power handling, and thermal considerations. We’ll also explore environmental factors, testing methods, applications, datasheet interpretation, and ultimately, how to choose the perfect transistor for your needs.

This detailed exploration of transistor specifications provides a practical and insightful approach to understanding the essential parameters of these fundamental electronic devices. We’ll analyze the characteristics, limitations, and potential of various transistors, allowing you to confidently navigate the intricacies of circuit design.

Transistor Types and Characteristics

Transistors are fundamental building blocks in modern electronics, enabling a wide range of functionalities. Understanding the diverse types and their unique characteristics is crucial for circuit design and application selection. This section delves into the specifics of Bipolar Junction Transistors (BJTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs).Different transistor types possess distinct properties, making them suitable for various applications. Choosing the appropriate transistor type is vital for optimizing circuit performance and minimizing power consumption.

Bipolar Junction Transistors (BJTs)

BJTs operate based on the controlled flow of current across a junction of two semiconductor materials. They are known for their relatively high current gain, which allows them to efficiently amplify signals.

- Current Gain (β): This parameter quantifies the ability of a BJT to amplify current. A higher β signifies a greater amplification capability. Typical values for β range from tens to hundreds. For example, a transistor with a β of 100 can amplify an input current 100 times.

- Voltage-Current Characteristics: BJTs exhibit a characteristic relationship between collector current and base current. This relationship is largely dependent on the base-emitter voltage and forms the basis for their amplification properties. The output characteristics, often displayed graphically, show how the collector current varies with the collector-emitter voltage.

- Typical Applications: BJTs are commonly employed in audio amplifiers, switching circuits, and high-power applications due to their high current handling capability. For instance, they are crucial in power supplies and motor control systems.

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs)

MOSFETs, unlike BJTs, utilize an electric field to control the flow of current. This characteristic allows them to exhibit high input impedance and low power consumption, making them well-suited for integrated circuits and low-power applications.

- Voltage Threshold (Vth): This parameter represents the gate-source voltage required to activate the MOSFET. A lower V th implies easier activation. The V th is a crucial factor in determining the operating range of the MOSFET.

- Input Impedance: MOSFETs typically exhibit extremely high input impedance, often in the giga-ohm range. This high input impedance minimizes the loading effect on the preceding circuit, preserving the signal integrity.

- Typical Applications: MOSFETs are frequently used in digital circuits, logic gates, and integrated circuits. Their low power consumption and high speed make them suitable for modern electronic devices like smartphones and computers.

Comparison of BJT and MOSFET

| Characteristic | BJT | MOSFET |

|---|---|---|

| Current Control | Current-controlled | Voltage-controlled |

| Input Impedance | Relatively low | Extremely high |

| Power Consumption | Higher | Lower |

| Switching Speed | Moderate | High |

| Applications | High-power circuits, amplifiers | Digital circuits, integrated circuits |

| Complexity | Simpler structure | More complex structure |

Electrical Specifications: Transistor Specs

Transistor electrical specifications are crucial for understanding their behavior and suitability for various circuit applications. These specifications define the limits and typical performance of the transistor, enabling designers to select appropriate components and predict circuit performance. Knowing these specifications is vital for ensuring reliable and efficient circuit operation.

Common Electrical Specifications

A comprehensive understanding of a transistor’s electrical characteristics is essential for circuit design. The table below Artikels common electrical specifications, providing typical and maximum values along with notes.

| Parameter Name | Units | Typical Value | Maximum Value | Meaning and Significance |

|---|---|---|---|---|

| Collector-Emitter Saturation Voltage (VCE(sat)) | Volts (V) | 0.1-0.3 | 0.5 | This voltage represents the voltage drop across the collector-emitter junction when the transistor is in saturation. A lower VCE(sat) is desirable for minimizing power dissipation in circuits where the transistor is frequently switching between on and off states. |

| Collector Current (IC) | Amperes (A) | 1-10 | 20 | The maximum collector current defines the maximum amount of current that can flow through the collector terminal. Exceeding this value can damage the transistor. |

| Base Current (IB) | Amperes (A) | 0.01-1 | 5 | The base current controls the collector current. A higher base current typically results in a higher collector current. The ratio of collector current to base current (β or hfe) is a critical parameter for amplifier circuits. |

| Collector-Emitter Breakdown Voltage (VCEO) | Volts (V) | 10-100 | 150 | This voltage defines the maximum reverse voltage that can be applied across the collector-emitter junction without causing a breakdown. Exceeding this voltage can lead to permanent damage of the transistor. |

| Current Gain (β or hfe) | Unitless | 50-300 | N/A | A measure of the transistor’s ability to amplify current. A higher value signifies a greater amplification capability, important for amplifier circuits. Note that this is a typical value, not a maximum value. |

| Cutoff Frequency (fT) | Hertz (Hz) | 100MHz-1GHz | N/A | This frequency indicates the upper frequency limit of the transistor’s ability to amplify signals. Higher values are advantageous in high-frequency applications like radio circuits. |

Impact on Circuit Design

These specifications directly impact circuit design decisions. For example, a low V CE(sat) is essential for high-speed switching applications, whereas a high V CEO is critical for ensuring reliable operation in circuits with high voltage swings. The current gain (β) is crucial for amplifier circuit design, determining the amplification factor and output current capabilities. The cutoff frequency (f T) plays a significant role in high-frequency applications, dictating the maximum frequency range where the transistor can operate effectively.

Relationship Between Transistor Parameters

The relationship between different transistor parameters is crucial for comprehensive circuit analysis. A higher current gain (β) generally correlates with a higher collector current for a given base current. Similarly, the cutoff frequency (f T) is often inversely proportional to the capacitance of the transistor, affecting its high-frequency performance. A detailed understanding of these interdependencies allows for the selection of transistors that best meet the specific requirements of the circuit design.

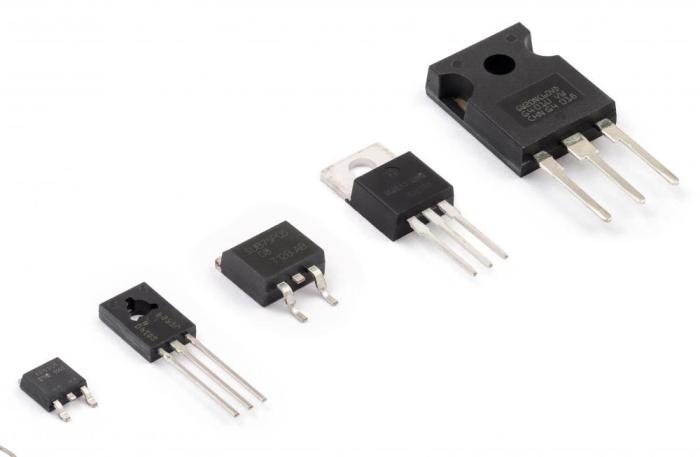

Packaging and Dimensions

Transistor packages are crucial for physical integration into circuits and systems. Proper package design significantly impacts heat dissipation, signal integrity, and overall performance. Different package types are tailored to specific applications and requirements, balancing size, cost, and performance characteristics.

Common Transistor Packages

Various package types exist, each optimized for distinct purposes. Understanding the common package types allows for appropriate selection based on application needs. Key package types include TO-220, TO-92, SOT-23, and various surface mount packages.

Typical Dimensions

Package dimensions directly affect the amount of heat a transistor can dissipate. Smaller packages, while offering space savings, may limit heat dissipation, potentially impacting reliability and lifespan. Larger packages generally provide more thermal surface area, enhancing cooling capabilities.

Heat Dissipation Considerations

The package’s design plays a vital role in heat dissipation. The material, geometry, and surface area of the package determine how efficiently heat can be transferred away from the transistor. Good heat sinking is crucial to prevent overheating and ensure reliable operation, especially in high-power applications. Proper thermal management extends the transistor’s lifespan and prevents performance degradation.

Signal Integrity Considerations

Signal integrity is also influenced by the package design. The package’s layout and material properties affect signal propagation and noise levels. Minimizing parasitic capacitances and inductances within the package structure is critical to maintain signal fidelity, particularly in high-speed applications. Package design directly impacts the overall performance of the circuit, and appropriate choices are crucial for high-frequency operations.

Package Types and Dimensions

| Package Type | Description | Typical Dimensions (approximate) | Illustration |

|---|---|---|---|

| TO-220 | A metal can package with a finned heat sink, widely used for medium-power transistors. | Length: 15mm, Width: 7mm, Height: 5mm | Imagine a small, cylindrical metal container with fins protruding from its surface. |

| TO-92 | A smaller plastic package, commonly used for low-power transistors. | Length: 5mm, Width: 3mm, Height: 2mm | Visualize a small, rectangular plastic casing. |

| SOT-23 | A very small surface mount package, commonly used for low-power integrated circuits, including transistors. | Length: 3mm, Width: 2mm, Height: 1mm | Picture a tiny, rectangular package, typically soldered directly to a printed circuit board. |

| Surface Mount Package (various) | A wide range of surface mount packages exist with diverse shapes and sizes. | Variable, depending on the specific package type. | Envision various rectangular, square, or other shaped packages designed for direct soldering to circuit boards. |

Frequency Response

Transistor frequency response is a crucial aspect of their performance, dictating how they behave at various frequencies. Understanding this characteristic is vital for selecting the appropriate transistor for a specific application, as it directly impacts the circuit’s ability to handle signals effectively. Different transistors exhibit varying frequency responses, with some excelling at high frequencies while others perform better at lower frequencies.The frequency response of a transistor defines its ability to amplify or switch signals at different frequencies.

This response is characterized by a gradual decrease in gain as the frequency increases. This decline is a fundamental limitation inherent to transistor design and operation. Factors such as the transistor’s internal capacitances and the nature of the signal itself influence the frequency response.

Frequency Response Characteristics

Transistors, like other electronic components, aren’t equally effective at all frequencies. Their performance degrades as the frequency increases. This is a direct consequence of the transistor’s internal structure and the physical processes governing its operation. These characteristics are critical for evaluating the transistor’s suitability for specific applications.

Impact of Frequency on Transistor Performance

Frequency directly impacts the transistor’s ability to amplify or switch signals. As the frequency of the input signal increases, the transistor’s gain decreases. This decrease is due to the internal capacitances and inductances within the transistor structure, which impede the flow of current at higher frequencies. Higher frequencies require faster switching, placing higher demands on the transistor’s internal components, ultimately affecting its ability to efficiently amplify or switch signals.

Relationship Between Frequency and Gain

The relationship between frequency and gain is inversely proportional. As frequency increases, the gain of the transistor typically decreases. This decrease in gain is a characteristic feature of transistor operation and is often modeled using a frequency response curve. The shape of this curve depends on the specific transistor type and the circuit in which it is used.

For example, a common-emitter amplifier configuration will exhibit a specific gain roll-off rate at higher frequencies.

Significance of Cutoff Frequency and Bandwidth

Cutoff frequency is the frequency at which the transistor’s gain drops to a specified value, often 70.7% (or -3dB) of its mid-band gain. Bandwidth is the range of frequencies over which the transistor’s gain remains within a specified tolerance. Both parameters are critical in determining the frequency range over which the transistor can effectively operate. A wider bandwidth means the transistor can handle a broader range of frequencies without significant gain loss.

For example, audio amplifiers typically require a wider bandwidth than radio frequency (RF) amplifiers. Cutoff frequency and bandwidth are crucial factors when selecting transistors for specific applications, ensuring they meet the required frequency range for optimal performance.

Power Handling Capacity

Transistor power handling capacity is a critical parameter determining their suitability for various applications. It signifies the maximum power a transistor can safely dissipate without experiencing damage or performance degradation. Understanding this capacity is essential for selecting the appropriate transistor type for a specific application and ensuring reliable operation under diverse conditions.Different transistor types exhibit varying power handling capabilities, which are influenced by factors like their physical structure, materials, and design.

Power dissipation, a critical aspect of transistor performance, directly impacts their operational limits. High power transistors are essential components in high-power electronic systems, and their application domains span diverse sectors.

Power Dissipation Effects

Power dissipation in transistors leads to temperature rise. Excessive heat can cause thermal runaway, potentially damaging the device. This thermal effect is crucial in determining the operational limits of transistors. Minimizing power dissipation through efficient circuit design and heat management techniques is paramount to maximize transistor lifespan and reliability. Appropriate heatsinking solutions are vital for high-power applications to prevent overheating.

High-Power Transistor Types

High-power transistors are specifically designed to handle substantial power levels. Different types of transistors are suitable for various power levels. Examples include power MOSFETs, bipolar junction transistors (BJTs), and insulated gate bipolar transistors (IGBTs). These devices find widespread applications in power converters, motor drives, and high-power amplifiers.

Comparison of Power Handling Capacity

| Transistor Type | Typical Power Handling Capacity (Watts) | Applications |

|---|---|---|

| Power MOSFETs | From tens of watts to several kilowatts | Switching power supplies, motor drives, inverters |

| BJTs | From several watts to hundreds of watts | High-power amplifiers, audio systems, switching circuits |

| IGBTs | From hundreds of watts to several kilowatts | Motor drives, power converters, inverters |

| Other specialized high-power transistors | May exceed kilowatts in certain designs | Industrial applications requiring high power output |

The table above provides a general overview of power handling capacities for various transistor types. Actual values can vary significantly based on specific device characteristics and design parameters. For instance, the exact power handling capacity of a particular MOSFET model depends on factors such as the device’s geometry, material properties, and the specific operating conditions.

Examples of High-Power Transistor Applications

Power transistors are integral components in numerous applications. In electric vehicle (EV) motor drives, high-power MOSFETs are used for efficient and reliable power conversion. Similarly, in high-power audio amplifiers, power BJTs are often employed to deliver high-fidelity sound output. Industrial systems frequently utilize IGBTs for controlling high-power motors, showcasing the versatility of this technology.

Thermal Considerations

Transistors, despite their small size, generate heat during operation. Proper thermal management is crucial for reliable and consistent performance. Ignoring thermal considerations can lead to reduced lifespan, unpredictable behavior, and potential damage to the device. This section delves into the thermal characteristics of transistors, emphasizing the importance of heat sinking and effective thermal management strategies.Thermal management is essential for maintaining optimal transistor performance and ensuring a long operational lifespan.

Excessive heat can lead to a degradation of electrical properties and even permanent damage. The following sections provide details on junction temperature, heat dissipation calculations, and effective cooling methods.

Junction Temperature and its Impact

Junction temperature is the temperature at the semiconductor junction within the transistor. Maintaining a safe operating junction temperature range is paramount for transistor reliability. Exceeding this limit can lead to accelerated degradation, reduced performance, and potentially catastrophic failure. High junction temperatures lead to increased carrier recombination rates and can alter the material properties, which can cause changes in the transistor’s characteristics.

Heat Sinking and Thermal Management

Heat sinking is a crucial aspect of thermal management. A heat sink is a passive component designed to transfer heat away from the transistor’s junction to the surrounding environment. The effectiveness of heat sinking depends on its thermal conductivity, surface area, and the method of mounting. Choosing the correct heat sink type and size is essential for maintaining a safe operating junction temperature.

Methods for Calculating Heat Dissipation, Transistor specs

Calculating heat dissipation involves considering several factors. The power dissipated by the transistor, the thermal resistance between the junction and the heat sink, and the ambient temperature are key parameters. The following equation represents the basic relationship:

Junction Temperature (Tj) = Power Dissipation (Pd)

Thermal Resistance (Rth) + Ambient Temperature (Ta)

This equation illustrates that a lower thermal resistance results in a lower junction temperature for the same power dissipation.

Methods for Determining Transistor Temperature

Several methods can be used to measure or estimate the transistor’s temperature. These include:

- Thermal Imaging: Specialized cameras can capture thermal images of the transistor, allowing for visualization of temperature distribution. Variations in the heat signature can highlight areas of higher or lower temperature, helping identify potential hotspots or areas requiring improved cooling.

- Temperature Sensors: Integrated temperature sensors can provide real-time readings of the junction temperature. These sensors can be integrated into the transistor package or attached to the heat sink for precise monitoring.

- Thermal Resistance Measurements: Measurements of thermal resistance between the transistor junction and the heat sink provide a valuable metric for assessing the effectiveness of the cooling solution. This allows for the calculation of the junction temperature based on the known power dissipation and ambient temperature.

The chosen method will depend on the application and the required accuracy.

Examples of Thermal Management Strategies

Different applications require specific thermal management strategies. For example, high-power transistors used in industrial settings might require large, highly conductive heat sinks and potentially forced air cooling. On the other hand, smaller transistors used in consumer electronics may use a combination of thermal grease and smaller, more compact heat sinks.

Environmental Factors

Transistor performance is susceptible to fluctuations in environmental conditions. Understanding how temperature, humidity, and other factors impact these components is crucial for ensuring reliable operation and longevity in various applications. This section details the effects of environmental elements on transistors and the importance of thorough environmental testing.

Impact of Temperature

Temperature variations significantly affect transistor characteristics. Increased temperature generally leads to higher leakage currents and reduced gain, while lower temperatures can cause a decrease in carrier mobility, leading to slower switching speeds. This is particularly relevant in high-power applications where heat dissipation is critical. For instance, the performance of a transistor in a mobile phone’s processor can be significantly impacted by the ambient temperature of the device.

Maintaining an appropriate operating temperature range is therefore crucial for optimal performance.

Impact of Humidity

High humidity levels can lead to increased surface leakage currents and corrosion, which can degrade transistor performance and reliability. Moisture absorption can alter the dielectric properties of insulating materials within the transistor structure, leading to short circuits. The effect of humidity is more pronounced in devices exposed to outdoor environments or those operated in high-humidity conditions. The impact on the reliability of the transistor is more profound when coupled with high temperatures.

Impact of Other Environmental Factors

Other environmental factors, such as radiation, pressure, and vibration, can also influence transistor performance. Exposure to radiation can cause damage to the semiconductor material, potentially altering the device’s characteristics and reducing its lifespan. Pressure variations can affect the device’s performance by influencing the operation of internal components. Vibration, particularly in harsh environments, can lead to mechanical stress and potentially damage internal connections.

Importance of Environmental Testing

Comprehensive environmental testing is essential for assessing the reliability and performance of transistors under various operating conditions. This involves subjecting transistors to simulated or real-world environmental stressors, including extreme temperatures, high humidity, and exposure to radiation. These tests help identify potential weaknesses and failures, allowing for design improvements and the development of more robust transistor structures. A well-designed environmental testing protocol can identify critical issues like moisture susceptibility and thermal instability before mass production, which significantly reduces costs associated with product recalls or repairs later.

Environmental Factors and their Impact on Transistors

| Environmental Factor | Impact on Transistors |

|---|---|

| Temperature | Higher temperatures lead to higher leakage currents and reduced gain; lower temperatures decrease carrier mobility, slowing switching speeds. |

| Humidity | High humidity increases surface leakage currents and corrosion, potentially leading to short circuits and reduced performance. |

| Radiation | Exposure to radiation can damage the semiconductor material, altering characteristics and reducing lifespan. |

| Pressure | Pressure variations can affect internal components, influencing transistor operation. |

| Vibration | Vibration can lead to mechanical stress and damage to internal connections, reducing reliability. |

Testing and Measurement

Accurate testing is crucial for ensuring transistors meet the specified performance criteria. Various methods and instruments are employed to evaluate critical parameters like current gain, voltage drop, and frequency response. These tests are essential for quality control and guarantee reliable transistor operation in diverse electronic circuits.

Common Transistor Parameter Testing Methods

Several techniques are employed to determine the electrical characteristics of transistors. These methods typically involve applying controlled stimuli and measuring resulting responses. Common methods include DC and AC measurements, utilizing specialized test equipment to precisely characterize the transistor’s behavior. These methods can be further categorized as static and dynamic tests.

Equipment for Transistor Parameter Testing

A range of instruments is used for testing transistor parameters. These instruments are vital for precise measurements, enabling the determination of critical transistor characteristics. Essential equipment includes multimeters, function generators, oscilloscopes, and specialized transistor testers.

- Multimeters are fundamental tools for basic DC voltage, current, and resistance measurements. They are used to measure DC voltage across terminals, DC current through the transistor, and resistance between terminals. This is crucial for determining the basic electrical properties of the transistor.

- Function generators provide controlled AC signals. These signals are applied to the transistor to measure its behavior under varying AC conditions. The frequency and amplitude of the signals can be precisely adjusted to assess the frequency response of the transistor.

- Oscilloscopes display waveforms, enabling visual analysis of voltage and current variations. They are instrumental in examining the transient responses of transistors under dynamic conditions. This is crucial for analyzing the transistor’s response to changing signals, providing information on speed and accuracy.

- Specialized transistor testers are automated instruments designed specifically for evaluating transistor parameters. They automate the process, providing fast and accurate results, streamlining the testing process.

Procedure for Measuring Specific Transistor Characteristics

The procedure for measuring transistor characteristics varies based on the specific parameter being evaluated. However, a standard protocol involves controlled stimulation and precise measurement of responses.

Step-by-Step Guide for Transistor Parameter Measurement

- Preparation: Ensure the transistor is properly connected to the test equipment and that all connections are secure. Verify that the equipment is calibrated and functioning correctly.

- DC Current Gain (hFE): Apply a known base current (I B) to the transistor and measure the resulting collector current (I C). The current gain is calculated as the ratio of I C to I B.

hFE = I C / I B

- Cut-off Frequency (fT): Apply a sinusoidal signal to the transistor’s input, increasing the frequency until the gain drops to 0.707 of its low-frequency value. The frequency at this point is the cut-off frequency.

- Reverse Breakdown Voltage (VBR): Apply a reverse voltage across the collector-emitter junction and measure the voltage at which the current significantly increases. This voltage is the reverse breakdown voltage.

- Collector-Emitter Saturation Voltage (VCE(sat)): Apply a base current to saturate the transistor. Measure the voltage between the collector and emitter when the transistor is in saturation. This value represents the collector-emitter saturation voltage.

- Record and Analyze Results: Carefully record all measured values, ensuring accurate readings and appropriate units. Analyze the results to identify any deviations from expected values or potential issues.

Applications in Circuits

Transistors are fundamental components in modern electronics, enabling a wide range of functionalities in various circuits. Their ability to amplify, switch, and control current flow makes them indispensable for constructing complex and sophisticated electronic systems. Understanding their role in different circuit types is crucial for designing and analyzing these systems effectively.Transistors’ diverse characteristics allow for their use in a vast array of circuit applications.

The specific characteristics, like current gain, voltage thresholds, and frequency response, directly influence the performance of the circuits they are incorporated into. This section explores the crucial role transistors play in different circuits, from simple amplifiers to complex communication systems.

Transistor specifications are crucial for any device, especially high-end models like the high-end Realme. These components directly impact performance and efficiency. Understanding these specs is key to evaluating the overall capabilities of a device, especially in high-end mobile phone products.

Transistor Configurations

Different transistor configurations—common emitter, common collector, and common base—yield distinct characteristics that are tailored for specific circuit functions. These configurations alter the input and output relationships of the transistor, impacting circuit performance.

- Common Emitter Configuration: This configuration is widely used for amplification. It provides a high current gain, high voltage gain, and a good input impedance. This makes it suitable for applications requiring significant amplification and signal conditioning.

- Common Collector Configuration: This configuration, often called an emitter follower, is known for its high input impedance and low output impedance. This configuration is frequently used as a buffer amplifier, isolating the source from the load and preventing signal loss.

- Common Base Configuration: This configuration offers a high input impedance and a low output impedance. It provides a low voltage gain, but it’s suitable for applications where impedance matching is crucial and a high input impedance is needed.

Amplifiers

Transistors are central to amplification circuits, increasing the strength of an input signal. Their ability to control current flow allows for signal enhancement, crucial in many electronic devices.

- Operational Amplifiers (Op-Amps): Op-amps are crucial components in analog circuits. They consist of multiple transistors, providing high gain, high input impedance, and low output impedance, making them versatile in various analog signal processing applications.

- Audio Amplifiers: Transistors are integral to audio systems, amplifying audio signals from a source to a speaker. The characteristics of the transistor influence the output quality, from volume to fidelity.

Oscillators

Transistors play a key role in generating periodic signals, known as oscillations. Their inherent ability to amplify and feedback signals creates the required conditions for self-sustained oscillations.

- Wien Bridge Oscillator: This oscillator uses an operational amplifier and resistors and capacitors. The transistor in this case acts as a crucial component in the feedback loop, generating and maintaining the oscillating signal.

- Colpitts Oscillator: This oscillator configuration employs two capacitors and an inductor, with the transistor acting as the amplification element within the feedback network, producing the oscillating signal.

Switching Circuits

Transistors also serve as switches, rapidly changing between on and off states. This capability is vital in digital circuits, where signals represent binary values.

- Digital Logic Gates: Transistors are the fundamental building blocks in digital logic gates (AND, OR, NOT, etc.). Their switching behavior allows for the manipulation of binary data, enabling the complex operations within digital computers and other digital systems.

- Power Switching: High-power transistors are essential in applications like switching power supplies, where rapid switching of high currents is required. The transistor’s ability to handle high current and voltage makes it a suitable choice for these applications.

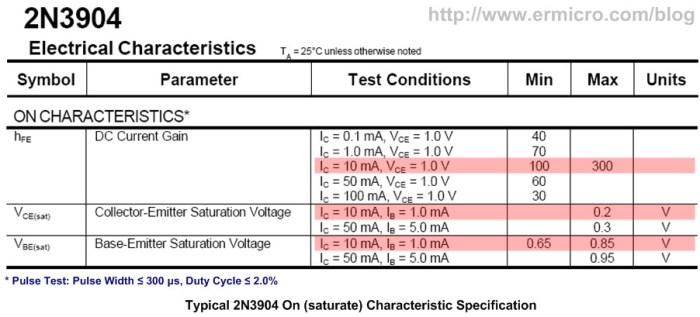

Datasheet Interpretation

Transistor datasheets are crucial for selecting and utilizing transistors correctly in electronic circuits. They provide a wealth of information about a transistor’s characteristics and capabilities. Understanding how to interpret these datasheets is essential for successful circuit design and troubleshooting.

Understanding Datasheet Structure

Datasheets typically follow a standardized format, making information easily accessible. They present key parameters and characteristics in a logical order. A typical datasheet will have sections dedicated to device description, electrical characteristics, mechanical specifications, and testing conditions. Understanding these sections allows for efficient information retrieval.

Extracting Relevant Information

A systematic approach to extracting relevant information is critical. Begin by identifying the specific transistor type and its application. Then, focus on the sections relevant to your circuit design, like the maximum current ratings, voltage limits, and operating frequencies. Refer to the specific test conditions noted in the datasheet for accurate interpretation of the provided parameters.

Understanding Symbols and Graphs

Datasheets often use graphical representations to present data. These graphs, or charts, provide a visual understanding of the transistor’s behavior under various conditions. Common graphs include those depicting current-voltage characteristics, transfer characteristics, and frequency response. Carefully review the axis labels and legends to correctly interpret the data.

Sample Datasheet with Annotations

This example illustrates a simplified datasheet for a common NPN bipolar junction transistor (BJT).

Device: 2N2222A NPN Bipolar Junction Transistor Electrical Characteristics (at 25°C unless otherwise specified) | Parameter | Symbol | Min | Typ | Max | Units | Test Conditions | |------------------------|--------|-----|-----|-----|-------|-----------------| | Collector-Emitter Voltage (V CEO) | V CEO | 30 | | 40 | V | IC = 10 mA, IB = 1 mA | | Collector Current (I C) | I C | 0.5 | 1.0 | 200 | mA | V CE = 10 V, I B = 1 mA | | Base Current (I B) | I B | 5 | | 100 | μA | V CE = 10 V, I C = 1 mA | | DC Current Gain (h FE) | h FE | 50 | | 300 | | I C = 1 mA, V CE = 10 V | Graphical Data (Current-Voltage Characteristics) [Graph illustrating typical collector current (I C) versus collector-emitter voltage (V CE) for various base currents (I B)] Note: The graph shows how collector current increases with base current, while collector-emitter voltage remains within specified limits. Packaging and Dimensions [Diagram illustrating the transistor's physical dimensions and pinout] Note: This diagram helps determine the physical layout and pin connections of the device.

Interpreting the Example

The sample datasheet provides crucial information about the transistor’s electrical characteristics.

The table displays parameters like maximum collector-emitter voltage (V CEO), collector current (I C), base current (I B), and DC current gain (h FE). The graph visually demonstrates the relationship between collector current and collector-emitter voltage under different base current conditions.

Transistor specs are crucial for modern tech, especially when considering the demands of durable virtual reality applications. Optimized transistor designs are key to ensuring the stability and responsiveness needed for a seamless VR experience. The high-performance transistors powering durable virtual reality systems need to be both efficient and robust, ultimately driving the future of VR.

This translates directly to the need for advanced transistor specs to meet the rigorous demands of VR.

Selecting the Right Transistor

Choosing the appropriate transistor for a specific application is crucial for circuit performance and reliability. Understanding the diverse characteristics and requirements of various transistors is vital for making informed decisions. A systematic approach to selection, considering key parameters, leads to optimized circuit design.

Selecting the correct transistor ensures the circuit functions as intended, with optimal performance and reliability. This involves a thorough evaluation of the application’s demands, aligning them with the transistor’s specifications. A well-chosen transistor will provide consistent performance, minimizing the risk of failure and maximizing the lifespan of the circuit.

Criteria for Transistor Selection

The selection process for a transistor hinges on several critical factors. Matching the transistor’s capabilities to the specific demands of the application is paramount. These criteria encompass the electrical characteristics, physical limitations, and environmental considerations.

- Electrical Characteristics: This encompasses parameters like current gain (β), voltage rating, and operating frequency. A transistor with insufficient current gain might not provide the desired amplification, while exceeding the voltage rating could lead to damage. Selecting a transistor with an adequate frequency response ensures that it can handle the intended signal speeds.

- Physical Limitations: The transistor’s physical dimensions, packaging type, and power dissipation capacity are important factors. Choosing a transistor with insufficient heat dissipation capability can result in overheating and premature failure. Compatibility with the available circuit board space and the required packaging type must be carefully evaluated.

- Environmental Factors: Operating temperature range, humidity, and other environmental conditions significantly impact transistor performance. Selecting a transistor designed for the expected environmental conditions ensures reliable operation in the target environment.

Decision-Making Process

A structured approach to selecting the right transistor is essential. This involves a step-by-step evaluation of the application’s needs, followed by a comparison of available transistor options. The process prioritizes matching the transistor’s specifications to the circuit’s requirements.

- Define Application Requirements: Clearly identify the specific needs of the circuit, including voltage, current, frequency response, and power handling capabilities. For example, a high-frequency amplifier will demand a different transistor than a low-power switching application.

- Identify Potential Transistor Candidates: Research and list available transistors that potentially meet the defined requirements. Consult datasheets and specifications to narrow down the choices. Consider reputable manufacturers and proven designs.

- Evaluate Transistor Specifications: Carefully compare the identified candidates based on the defined application requirements. Prioritize transistors that match the desired specifications. Consider factors such as maximum current, voltage, and power dissipation.

- Select the Optimal Transistor: Choose the transistor that best meets all the defined requirements. Thoroughly examine the datasheet for any additional specifications or caveats.

Transistor Selection Table

This table provides examples of criteria and considerations when selecting a transistor.

| Application | Required Criteria | Example Transistor |

|---|---|---|

| High-Frequency Amplifier | High frequency response, high gain, low noise | 2N4401 (BJT), 2SK170 (FET) |

| Low-Power Switching Circuit | Low power dissipation, fast switching speed | 2N2222 (BJT), IRF540 (FET) |

| High-Voltage Rectifier | High voltage rating, high current handling | 2N3055 (BJT), IRFP460 (FET) |

Last Point

In conclusion, this comprehensive guide to transistor specifications provides a deep dive into the crucial elements governing transistor performance. We’ve explored the key aspects of various transistor types, their electrical properties, packaging, and operational parameters. Armed with this knowledge, you’ll be well-equipped to select the optimal transistor for your specific application, maximizing circuit performance and reliability. Remember, understanding these specs is paramount for successful circuit design.

Helpful Answers

What are the common testing methods for transistor parameters?

Common testing methods include using a multimeter to measure parameters like current gain (hFE), voltage drop, and resistance. Specialized equipment, such as parameter analyzers, can provide more precise readings.

How does the power handling capacity of a transistor affect its performance?

Higher power handling capacity allows for more demanding applications but can increase the risk of overheating if not properly managed. Proper heat sinking and thermal management are essential.

What are some typical applications for MOSFET transistors?

MOSFETs are frequently used in switching applications, high-frequency circuits, and power electronics due to their high input impedance and low on-resistance.

How does junction temperature impact transistor reliability?

Excessive junction temperature can lead to degradation and failure of the transistor. Careful thermal management is critical for ensuring long-term reliability.